When you pick up a generic pill at the pharmacy, you expect it to work just like the brand-name version. But behind that simple promise is a complex battle against invisible threats-dust, microbes, chemical residues-that can turn a safe medicine into a dangerous one. In generic drug manufacturing, contamination control isn’t just a checklist item. It’s the difference between a life-saving treatment and a public health crisis.

Why Contamination Matters More in Generics

Generic drugs make up 90% of prescriptions in the U.S., but they account for only 22% of total spending. That means manufacturers operate on razor-thin margins. Cutting corners sounds tempting, but one contamination event can wipe out millions. The 2020 Valsartan recall, triggered by cancer-causing nitrosamines in raw materials, cost generic makers over $1.2 billion. That wasn’t an accident-it was a failure of contamination controls. The FDA doesn’t wait for disasters to act. In fiscal year 2022, nearly 37% of all warning letters sent to drug manufacturers were for contamination violations. That’s higher than any other quality issue. And it’s not just about dirty floors. Contamination can come from air, water, equipment, packaging, or even the people handling the product.How Contamination Happens in Generic Manufacturing

Think of a generic drug plant like a busy kitchen. One chef makes pasta, then without washing hands or changing tools, starts cooking curry. The result? A ruined dish. In pharma, that’s cross-contamination. Common sources include:- Shared equipment between different drugs, especially high-potency compounds like cancer drugs or hormones

- Inadequate cleaning between batches

- Dirty air in production rooms

- Improper gowning by staff

- Contaminated raw materials from overseas suppliers

The Rules: CGMP and Cleanroom Standards

The foundation of contamination control is Current Good Manufacturing Practices (CGMP). These aren’t suggestions. They’re federal law. Under 21 CFR 210.3(b)(3), a drug is adulterated if it’s made under unsanitary conditions that could harm patients. Facilities must follow strict cleanroom classifications:- ISO Class 5 (Grade A): For filling sterile products. No more than 3,520 particles per cubic meter at 0.5 microns or larger.

- ISO Class 7 (Grade C): For preparing solutions and packaging. Air must be changed 20-60 times per hour.

- ISO Class 8 (Grade D): For less critical areas like storage or administrative zones.

Cleaning Validation: Proving It’s Clean

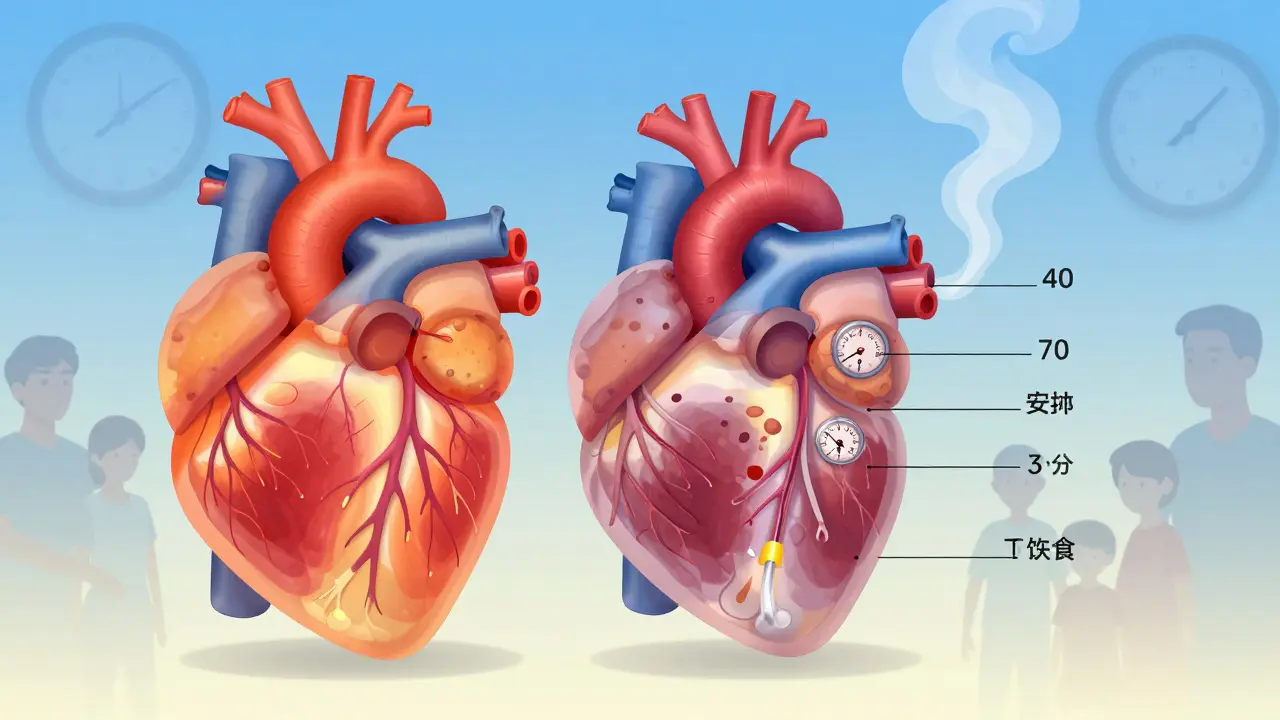

You can’t just say a machine is clean. You have to prove it. After making Drug A, the line must be cleaned before making Drug B. The standard? No more than 10 parts per million (ppm) of residue from the previous product. For microbial limits, it’s 10 colony-forming units (CFU) per 25 cm² of surface. How do you test that? Swabs, rinse water samples, and now, rapid microbiological methods (RMMs). Traditional culture tests take 5-7 days. RMMs give results in 24-48 hours. That’s a game-changer. If you find contamination on Friday, you can stop production before Monday’s batch is made. Some companies still use manual swabbing. That’s risky. The FDA found manual checks miss 78% of transient contamination events. Real-time particle counters-like the MetOne 3400+-track airborne particles every second. Facilities using them saw contamination incidents drop by 63%.Human Factors: The Biggest Risk

Dr. Michael Gamlen, a leading pharma consultant, says 83% of contamination events come from human behavior. Not because workers are lazy. Because systems are flawed. People get tired. After 8 hours on shift, gowning compliance drops 40%. Gloves tear. Hairnets slip. Shoes track in dirt. One Teva Pharmaceuticals facility saw a 30% spike in gowning violations after switching to reusable isolation gowns. They had to spend $185,000 on upgraded air showers to fix it. Simple fixes work. Color-coded equipment prevents mix-ups-red for blood pressure meds, blue for antibiotics. Dycem CleanZone mats underfoot reduce foot-borne contamination by 72%. Staggered shift changes cut traffic through clean zones. These aren’t fancy tech. They’re smart design.Technology Is Changing the Game

Big manufacturers are investing in AI and automation. Honeywell’s Forge Pharma system uses machine learning to predict contamination risks before they happen. In a pilot at a Merck generics plant, false alarms dropped by 68%. That means fewer shutdowns and more confidence. Real-time monitoring isn’t cheap. A single particle counter costs $15,000-$25,000. Full systems run $500,000-$2 million. That’s why only 89% of the top 50 generic makers use them-versus 37% of smaller plants. But the cost of not using them is higher. A single FDA warning letter can delay approval for months. And with FDA increasing inspection frequency by 27% for facilities with past violations, the risk is mounting.

The Future: HBELs and Continuous Manufacturing

By 2025, the FDA will require all generic manufacturers to establish Health-Based Exposure Limits (HBELs) for every product. This means calculating exactly how much of a previous drug residue is safe in the next batch-even if it’s just 1 nanogram per square centimeter. Implementing HBELs costs about $1.2 million per facility. For small companies, that’s a huge burden. But the alternative-being shut down-is worse. Newer methods like continuous manufacturing (ICH Q13, finalized in June 2023) are changing how drugs are made. Instead of making batches in large vats, ingredients flow through connected machines in real time. That reduces exposure points and makes contamination harder to spread. Sustainability is also pushing innovation. Waterless cleaning systems, tested at GlaxoSmithKline, cut utility costs by 22%. Less water, less waste, less risk.What Small Manufacturers Can Do

You don’t need a $2 million system to stay compliant. Start with the basics:- Implement one batch at a time-don’t run multiple products back-to-back without full cleaning.

- Use color-coded tools and zones to avoid mix-ups.

- Train staff daily, not just once a year. Gowning is a skill, not a chore.

- Use ATP bioluminescence testing. It gives you results in 5 minutes, not 5 days.

- Partner with a reliable raw material supplier. Indian sources have 22% higher contamination rates than EU suppliers, according to EDQM data.

Final Thought: It’s Not About Cost-It’s About Trust

Generic drugs exist because they make medicine affordable. But if patients lose trust in them, the whole system collapses. Contamination controls aren’t about being the fanciest plant. They’re about being the most reliable one. The data doesn’t lie: facilities that invest in smart, risk-based contamination controls see 3.2x better ROI over five years. Fewer recalls. Faster approvals. Fewer inspections. More confidence from regulators and patients alike. In the end, it’s not about spending more. It’s about spending smarter.What is considered adulteration in generic drugs?

Adulteration occurs when a drug is prepared, packed, or held under unsanitary conditions that could cause contamination with filth or make it harmful to health, as defined by 21 CFR 210.3(b)(3). This includes chemical residues, microbial growth, foreign particles, or cross-contamination from other drugs.

How often do generic drug manufacturers face contamination violations?

In 2022, contamination-related violations accounted for 37.2% of all FDA Warning Letters issued to pharmaceutical manufacturers. That’s the highest rate of any quality issue. Facilities with prior violations now face 27% more frequent inspections.

What’s the difference between ISO Class 5 and ISO Class 8 cleanrooms?

ISO Class 5 (Grade A) is for sterile filling operations and allows no more than 3,520 particles ≥0.5μm per cubic meter. ISO Class 8 (Grade D) is for less critical areas like storage and allows up to 35,200,000 particles per cubic meter. The higher the class number, the more contamination allowed.

Why is cleaning validation so important?

Cleaning validation proves that equipment is free of harmful residues from previous products. The standard is ≤10 ppm chemical residue and ≤10 CFU per 25 cm² for microbes. Without proof, regulators can reject batches or shut down production.

Can small generic manufacturers afford modern contamination controls?

Yes, but they must prioritize. Start with low-cost, high-impact steps: color-coded equipment, Dycem mats, ATP testing, and one-batch-at-a-time production. Real-time monitoring systems are expensive, but even basic cleaning validation with rapid methods can cut rejection rates by half. The goal isn’t to copy big pharma-it’s to meet regulatory minimums safely and consistently.

What’s the biggest mistake generic manufacturers make?

Relying on end-product testing instead of preventing contamination during production. The FDA calls this a fundamental CGMP violation. You can’t test contamination out of a batch-you have to stop it from getting in.

What’s the timeline for implementing new contamination rules?

The FDA’s new draft guidance on cross-contamination controls requires Health-Based Exposure Limits (HBELs) for all products by 2025. Implementation typically takes 18-24 months. Facilities that delay risk inspection failures, batch rejections, and potential shutdowns.

Christina Widodo

January 12, 2026 AT 10:17Wow this is wild I had no idea how much goes into making a generic pill safe

Like I just assume it’s the same as brand name but the level of control needed is insane

Especially the part about cross-contamination - imagine if your blood pressure med got mixed with chemo drugs

That’s not a mistake, that’s a nightmare

Prachi Chauhan

January 13, 2026 AT 06:04in india we make half the world’s generics but the factories? some are like old kitchens with fans blowing dust everywhere

no one talks about this but the truth is dirty machines + tired workers + no money = bad pills

we fix it with hope and prayers

Katherine Carlock

January 14, 2026 AT 08:11This is actually so important and no one talks about it outside pharma circles

People think generics are cheap so they’re low quality but the opposite is true

They have to be *more* controlled because margins are so tight

It’s like running a Michelin-star kitchen on a food truck budget

Sona Chandra

January 15, 2026 AT 17:13THE FDA IS LYING TO US

They let these Indian and Chinese plants ship out contaminated drugs because they’re too lazy to shut them down

My cousin died from a fake blood thinner and no one got punished

THIS IS MURDER BY REGULATION

Jennifer Phelps

January 15, 2026 AT 19:4310 ppm residue sounds like nothing but what if its a hormone or a carcinogen

and how do they even test that on every single batch

and why do we still use swabs when we have tech that works better

its like using a typewriter to file taxes

beth cordell

January 17, 2026 AT 19:00OMG I just realized my blood pressure meds might’ve been made in the same room as insulin 😱

That’s terrifying

Also color coded tools? YES PLEASE 🙌

Why isn’t this on TV??

Lelia Battle

January 19, 2026 AT 10:15The ethical weight of this topic is profound.

Generics are not merely commodities - they are lifelines for millions who cannot afford branded therapies.

When contamination occurs, it is not merely a regulatory failure - it is a breach of social contract.

We must demand transparency, not just compliance.

Cost-cutting cannot be prioritized over human dignity.

Technology is a tool, not a solution - human vigilance remains irreplaceable.

Perhaps the true measure of a society is not its wealth, but its commitment to the health of its most vulnerable.

Thank you for illuminating this silent crisis.

Rinky Tandon

January 21, 2026 AT 06:53HBELs? You mean Health-Based Exposure Limits? Please stop using acronyms like you’re trying to sound smart

Also your ‘small manufacturers’ advice is useless - if you can’t afford real-time particle counters you shouldn’t be making drugs

Period. End of story. Your ‘color-coded tools’ won’t stop cancer-causing nitrosamines

Either do it right or don’t do it at all

Alex Fortwengler

January 23, 2026 AT 01:29Big Pharma and the FDA are in cahoots

They want you to think generics are safe so you’ll stop buying the expensive ones

They let contamination slide because they profit from the recalls

Remember the Valsartan scandal? That was a cover-up

They knew for years and still sold it to grandma’s in Ohio

It’s all a scam

Monica Puglia

January 24, 2026 AT 13:46Thank you for writing this - seriously

People don’t realize how much work goes into making sure their meds don’t kill them

And the fact that small plants can still comply with low-cost fixes? That’s hope right there

Keep pushing for better systems, not just more money

👏👏👏

steve ker

January 25, 2026 AT 10:45Generic drugs are for peasants

Real people take brand name

Why waste time reading this

George Bridges

January 25, 2026 AT 22:08I’ve worked in a small generic plant in Ohio - the staff were the most careful people I’ve ever met

They knew every batch could be someone’s last chance

It’s not about the money, it’s about the people

Thanks for giving them a voice

Rebekah Cobbson

January 26, 2026 AT 02:54One batch at a time is the golden rule - no exceptions

And ATP testing? Game changer. You can test a surface in 5 minutes and know if it’s safe

Don’t wait for an FDA inspection to start caring

Start today - your patient’s life depends on it

Audu ikhlas

January 26, 2026 AT 20:25India makes the best generics in the world

US and EU are just jealous because they can’t produce at this scale

Stop blaming our factories for your lazy regulators

Our workers work 16 hour days so your kids can breathe

Shut up and pay more if you want perfection